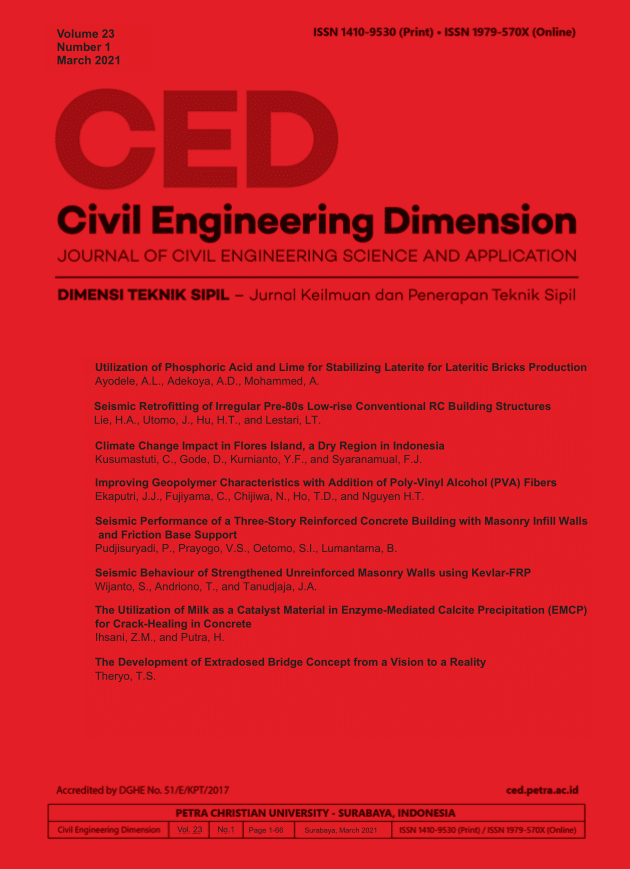

Improving Geopolymer Characteristics with Addition of Poly-Vinyl Alcohol (PVA) Fibers

DOI:

https://doi.org/10.9744/ced.23.1.28-34Keywords:

Geopolymer, PVA, fly ash, mechanical properties, alkali ratioAbstract

This paper presents the benefits of PVA fibers in improving the mechanical properties of class F fly-ash-based geopolymer concrete. The activator used in the geopolymer was 8M sodium hydroxide (NaOH) and sodium silicate (Na2SiO3), with a mass ratio of Na2SiO3 to NaOH varied from 1.5 to 2.5. Cylindrical specimens with a diameter of 100 mm and a height of 200 mm were prepared for mechanical strength tests. The PVA fibers in the geopolymers were fixed at 0.4%, 0.6%, and 0.8% by total volume. Some mechanical tests were carried out, including compression, splitting, direct tensile and elastic modulus tests. It was found that the mixture with a ratio of alkalis of 1.5 and the PVA fiber content of 0.4% had the best workability. The highest compressive strength was obtained in a mixture with alkali activator ratios of 1.5 and 2.0, and with 0.6% fiber addition. The ratio of the tensile (and splitting-tensile) strength to compressive strength was found to increase with the certain amount of PVA fibers and the ratio of the alkali activators. The workability issue and fiber direction in the concrete were the dominant factors influencing the properties of geopolymer concrete.

References

Davidovits, J. Geopolymer Cement for mitigation of Global Warming. 2014 [cited 2015 Augustus 8]; Available from: http://www.geopolymer.org/applications/global-warming/.

Davidovits, J., Geopolymers. Journal of thermal analysis, 1991. 37(8): p. 1633-1656.

Hardjito, D., et al., On the Development of Fly Ash-Based Geopolymer Concrete. Aci Materials Journal, 2004. 101(6): p. 467-472.

Hashim, A.N., et al., Effect of sodium hydroxide (NaOH) concentration on compressive strength of alkali-activated slag (AAS) mortars. Appl. Mech. and Mater., 2015. 754-755: p. 300-304.

Subaer, et al., The influence of Si:Al and Na:Al on the physical and microstructure characters of geopolymers based on metakaolin. Mater. Sci. Forum, 2016. 841: p. 170-177.

Abdullah, M.M.A.B., et al., Study on the geopolymer concrete properties reinforced with hooked steel fiber, in IOP Conference Series: Materials Science and Engineering. 2017.

Araújo, D.L., et al., Influence of steel fibers on the reinforcement bond of straight steel bars. IBRACON Structures and Materials Journal, 2013. 6(2): p. 307-338.

Behnood, A. and M. Ghandehari, Comparison of compressive and splitting tensile strength of high-strength concrete with and without polypropylene fibers heated to high temperatures. Fire Safety Journal, 2009. 44(8): p. 1015-1022.

Ekaputri, J.J., S. Junaedi, and Wijaya. Effect of curing temperature and fiber on metakaolin-based geopolymer. in SCESCM 2016. 2017. Procedia Eng.

Harajli, M.H., M. Hout, and W. Jalkh, Local bond stress-slip behavior of reinforcing bars embedded in plain and fiber concrete. ACI Materials Journal, 1995. 92(4): p. 343-353.

Manfaluthy, M.L. and J.J. Ekaputri. The Application of PVA Fiber to Improve the Mechanical Properties of Geopolymer Concrete. in EACEF 2017. 2017. Seoul: MATEC Web of Conferences.

Nematollahi, B., et al., High ductile behavior of a polyethylene fiber-reinforced one-part geopolymer composite: A micromechanics-based investigation. Archives of Civil and Mechanical Engineering, 2017. 17(3): p. 555-563.

Nematollahi, B., J. Sanjayan, and F.U.A. Shaikh, Comparative deflection hardening behavior of short fiber reinforced geopolymer composites. Construction and Building Materials, 2014. 70: p. 54-64.

Ohno, M. and V.C. Li, A feasibility study of strain hardening fiber reinforced fly ash-based geopolymer composites. Construction and Building Materials, 2014. 57: p. 163-168.

Tekle, B.H., A. Khennane, and O. Kayali, Bond properties of glass fibre reinforced polymer bars with fly-ash based geopolymer concrete, in ICCST/10. 2015, IDMEC 2015.

Tanyildizi, H. and Y. Yonar, Mechanical properties of geopolymer concrete containing polyvinyl alcohol fiber exposed to high temperature. Construction and Building Materials, 2016. 126: p. 381-387.

Xu, F., et al., Mix design and flexural toughness of PVA fiber reinforced fly ash-geopolymer composites. Construction and Building Materials, 2017. 150: p. 179-189.

International, A., ASTM C 39 in Standard test method for compressive strength of cylindrical concrete specimens. 2003.

International, A., ASTM C 496M, in Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. 2011.

Ekaputri, J.J., H. Limantono, and Triwulan, Effect of PVA fiber in increasing mechanical strength on paste containing glass powder. Key Engineering Materials, 2016. 673: p. 83-93.

Trindade, A.C.C., P.H.R. Borges, and F. de Andrade Silva, Mechanical behavior of strain-hardening geopolymer composites reinforced with natural and PVA fibers. Materials Today: Proceedings, 2019. 8: p. 753-759.

Xu, S., et al., Influence of the PVA fibers and SiO2 NPs on the structural properties of fly ash based sustainable geopolymer. Construction and Building Materials, 2018. 164: p. 238-245.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with this journal agree to the following terms:- Authors retain the copyright and publishing right, and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) followingthe publication of the article, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).