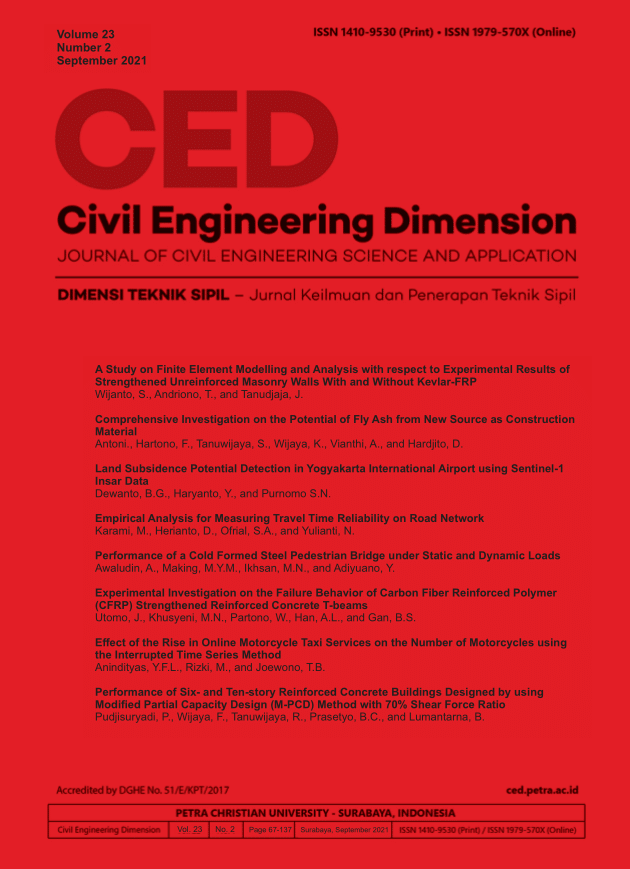

Comprehensive Investigation on the Potential of Fly Ash from New Source as Construction Material

DOI:

https://doi.org/10.9744/ced.23.2.78-90Keywords:

fly ash, alternative binder, pozzolan, HVFA, self-cementing, geopolymer, calcium hydroxideAbstract

Fly ash has been highly advocated to be re-utilized as a construction material. The most common utilization is to partially replace cement in a low-percentage scheme. However, there are several other schemes available to potentially use fly ash as binder in concrete that have not been widely exercised, especially those utilizing it in high to very high volume. In those schemes, high-volume fly ash (HVFA) concrete might use more than 50% fly ash to replace cement. To exploit its self-cementing properties, with or without the addition of other compounds, such as calcium hydroxide, fly ash might be used in very high percentage of cement replacement. In geopolymeric system, fly ash acts as the precursor of a stable binder, with the presence of highly alkaline solution. This paper demonstrates a model to investigate the potential of fly ash in several binder systems. The results show that fly ash from a good source can be utilized as an alternative binder in several different schemes.

References

Cornot-Gandolphe, S., Indonesia’s electricity demand and the coal sector: export or meet domestic demand?, (2017).

Ordonez, J.A., Jakob, M., Steckel, J.C., and Fünfgeld, A., Coal, power and coal-powered politics in Indonesia, Environmental Science & Policy. 123 (2021) 44–57. https://doi.org/10.1016/j.envsci.2021.05.007.

Edwards, G.A.S., Coal and climate change, Wiley Interdisciplinary Reviews: Climate Change. 10 (2019) e607.

Fauzi, A., Nuruddin, M.F., Malkawi, A.B., and Abdullah, M.M.A.B., Study of fly ash characterization as a cementitious material, Procedia Engineering. 148 (2016) 487–493.

Ali, M.B., Saidur, R., and Hossain, M.S., A review on emission analysis in cement industries, Renewable and Sustainable Energy Reviews. 15 (2011) 2252–2261.

Ahmaruzzaman, M., A review on the utilization of fly ash, Progress in Energy and Combustion Science. 36 (2010) 327–363.

Yao, Z.T., Ji, X.S., Sarker, P.K., Tang, J.H., Ge, L.Q., Xia, M.S., and Xi, Y.Q., A comprehensive review on the applications of coal fly ash, Earth-Science Reviews. 141 (2015) 105–121.

Feng, X., and Clark, B., Evaluation of the physical and chemical properties of fly ash products for use in Portland cement concrete, in: World Coal Ash Conf., 2011: pp. 1–8.

Wang, Z., and Song, Y., Adsorption properties of CFBC ash – cement pastes as compared with PCC fly ash – cement pastes, International Journal of Coal Science & Technology. 3 (2016) 62–67. https://doi.org/10.1007/s40789-016-0103-8.

Siddique, S., and Jang, J.G., Effect of CFBC ash as partial replacement of PCC ash in alkali-activated material, Construction and Building Materials. 244 (2020) 118383.

Antoni, Gunawan, R., and Hardjito, D., Rapid indicators in detecting variation of fly ash for making HVFA concrete, Applied Mechanics and Materials. 815 (2015) 153–157. https://doi.org/10.4028/www.scientific.net/AMM.815.153.

Chen, H.-J., Shih, N.-H., Wu, C.-H., and Lin, S.-K., Effects of the loss on ignition of fly ash on the properties of high-volume fly ash concrete, Sustainability. 11 (2019) 2704.

Antoni, Widianto, A.K., Wiranegara, J.L., and Hardjito, D., Consistency of fly ash quality for making high volume fly ash concrete, Jurnal Teknologi. 79 (2017) 13–20. https://doi.org/10.11113/jt.v79.11870.

Antoni, Wibiatma Wijaya, S., and Hardjito, D., Factors Affecting the Setting Time of Fly Ash - Based Geopolymer, Materials Science Forum. 841 (2016) 90–97. https://doi.org/10.4028/www.scientific.net/MSF.841.90.

Antoni, Wibawa, H.S., and Hardjito, D., Influence of Particle Size Distribution of High Calcium Fly Ash on HVFA Mortar Properties, Civil Engineering Dimension. 20 (2019) 51–56. https://doi.org/10.9744/CED.20.2.51-56.

Rivera, F., Martínez, P., Castro, J., and López, M., Massive volume fly-ash concrete: A more sustainable material with fly ash replacing cement and aggregates, Cement and Concrete Composites. 63 (2015) 104–112. https://doi.org/10.1016/j.cemconcomp.2015.08.001.

Huang, C.H., Lin, S.K., Chang, C.S., and Chen, H.J., Mix proportions and mechanical properties of concrete containing very high-volume of Class F fly ash, Construction and Building Materials. 46 (2013) 71–78. https://doi.org/10.1016/j.conbuildmat.2013.04.016.

Shaikh, F.U.A., Supit, S.W.M., and Sarker, P.K., A study on the effect of nano silica on compressive strength of high volume fly ash mortars and concretes, Materials and Design. 60 (2014) 433–442. https://doi.org/10.1016/j.matdes.2014.04.025.

Rashad, A.M., A brief on high-volume Class F fly ash as cement replacement – A guide for Civil Engineer, International Journal of Sustainable Built Environment. 4 (2015) 278–306. https://doi.org/10.1016/j.ijsbe.2015.10.002.

Bentz, D.P., and Ferraris, C.F., Rheology and setting of high volume fly ash mixtures, Cement and Concrete Composites. 32 (2010) 265–270. https://doi.org/10.1016/j.cemconcomp.2010.01.008.

Hoyos-Montilla, A.A., Puertas, F., and Tobón, J.I., Microcalorimetric study of the effect of calcium hydroxide and temperature on the alkaline activation of coal fly ash, Journal of Thermal Analysis and Calorimetry. 131 (2018) 2395–2410.

Roskos, C., Cross, D., Berry, M., and Stephens, J., Identification and Verification of Self-Cementing Fly Ash Binders for “ Green ” Concrete, 2011 World of Coal Ash (WOCA) Conference. (2011). http://www.flyash.info/.

Do, T.M., Kang, G.-O., and Kim, Y., Development of a new cementless binder for controlled low strength material (CLSM) using entirely by-products, Construction and Building Materials. 206 (2019) 576–589.

Mackiewicz, S.M., and Ferguson, E.G., Stabilization of soil with self-cementing coal ashes, World of Coal Ash (WOCA). (2005) 1–7.

Cross, D., Stephens, J., and Vollmer, J., Structural Applications of 100 Percent Fly Ash Concrete, in: World Coal Ash Conferr., 2005.

Gotti, E., Oleson, J.P., Bottalico, L., Brandon, C., Cucitore, R., and Hohlfelder, R.L., A comparison of the chemical and engineering characteristics of ancient Roman hydraulic concrete with a modern reproduction of Vitruvian hydraulic concrete, Archaeometry. 50 (2008) 576–590.

Luxán, M.P. de, De Rojas, M.I.S., and Frías, M., Investigations on the fly ash-calcium hydroxide reactions, Cement and Concrete Research. 19 (1989) 69–80.

Biernacki, J.J., Williams, P.J., and Stutzman, P.E., Kinetics of reaction of calcium hydroxide and fly ash, ACI Materials Journal. 98 (2001) 340–349.

Hlaváček, P., Šulc, R., Šmilauer, V., Rößler, C., and Snop, R., Ternary binder made of CFBC fly ash, conventional fly ash, and calcium hydroxide: Phase and strength evolution, Cement and Concrete Composites. 90 (2018) 100–107. https://doi.org/10.1016/j.cemconcomp.2017.09.020.

Djwantoro Hardjito, Steenie E Wallah, Dody M.J. Sumajouw, B.V Rangan, Hardjito, D., Wallah, S.E., Sumajouw, D.M.J., and Rangan, B. V, Factors influencing the compressive strength of fly ash-based geopolymer concrete, Civil Engineering Dimension. 6 (2007) 88–93. https://doi.org/10.9744/ced.6.2.pp. 88-93.

Antoni, Wijaya, S.W., Satria, J., Sugiarto, A., and Hardjito, D., The use of borax in deterring flash setting of high calcium fly ash based geopolymer, Materials Science Forum. 857 (2016) 416–420. https://doi.org/10.4028/www.scientific.net/MSF.857.416.

Antoni, A., Purwantoro, A.A.T., Suyanto, W.S.P.D., and Hardjito, D., Fresh and Hardened Properties of High Calcium Fly Ash-Based Geopolymer Matrix with High Dosage of Borax, Iranian Journal of Science and Technology - Transactions of Civil Engineering. 44 (2020) 535–543. https://doi.org/10.1007/s40996-019-00330-7.

Mustafa, M., Bakri, A., Mohammed, H., Kamarudin, H., Niza, I.K., Zarina, Y., Bakri, M. Al, and Mohammed, H., Review on fly ash-based geopolymer concrete without Portland Cement, Journal of Engineering and Technology Research. 3 (2011) 1–4.

Wattimena, O.K., Antoni, and Hardjito, D., A review on the effect of fly ash characteristics and their variations on the synthesis of fly ash based geopolymer, AIP Conference Proceedings. 1887 (2017). https://doi.org/10.1063/1.5003524.

Antoni, Wijaya, S.W., and Hardjito, D., Factors affecting the setting time of fly ash-based geopolymer, Materials Science Forum. 841 (2016) 90–97. https://doi.org/10.4028/www.scientific.net/MSF.841.90.

ASTM C778, Standard specification for sand, 14 (2014) 1–3. https://doi.org/10.1520/C0778-13.2.

ASTM D5239, Standard practice for characterizing fly ash for use in soil stabilization, ASTM International, West Conshohocken, PA, 2012. https://doi.org/10.1520/D5239-04.2.

ASTM C187, Standard test method for amount of water required for normal consistency of hydraulic cement paste, ASTM International, West Conshohocken, PA, 2016. https://doi.org/10.1520/C0187-16.

ASTM C1437, Standard Test Method for Flow of Hydraulic Cement Mortar, ASTM International, West Conshohocken, PA, 2012. https://doi.org/10.1520/C1437-07.2.

ASTM C403, Standard test method for time of setting of concrete mixtures by penetration resistance, ASTM International, West Conshohocken, PA, 2016. https://doi.org/10.1520/C0403_C0403M-16.

ASTM C109, Standard test method for compressive strength of hydraulic cement mortars, ASTM International, West Conshohocken, PA, 2013.

Antoni, Wijaya, S.W., and Hardjito, D., Compressive strength of geopolymer based on the fly ash variation, Materials Science Forum. 841 (2016) 98–103. https://doi.org/10.4028/www.scientific.net/MSF.841.98.

ASTM C618, Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete, ASTM International, West Conshohocken, PA, 2012. https://doi.org/10.1520/C0618.

Antoni, A., Satria, J., Sugiarto, A., and Hardjito, D., Effect of variability of fly ash obtained from the same source on the characteristics of geopolymer, in: MATEC Web Conf., 2017: pp. 9–13. https://doi.org/https://doi.org/10.1051/matecconf/20179701026.

Termkhajornkit, P., and Nawa, T., The fluidity of fly ash-cement paste containing naphthalene sulfonate superplasticizer, Cement and Concrete Research. 34 (2004) 1017–1024. https://doi.org/10.1016/j.cemconres.2003.11.017.

Rifaai, Y., Yahia, A., Mostafa, A., Aggoun, S., and Kadri, E.-H., Rheology of fly ash-based geopolymer: Effect of NaOH concentration, Construction and Building Materials. 223 (2019) 583–594.

Aupoil, J., Champenois, J.-B., de Lacaillerie, J.-B. d’Espinose, and Poulesquen, A., Interplay between silicate and hydroxide ions during geopolymerization, Cement and Concrete Research. 115 (2019) 426–432.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with this journal agree to the following terms:- Authors retain the copyright and publishing right, and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) followingthe publication of the article, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).