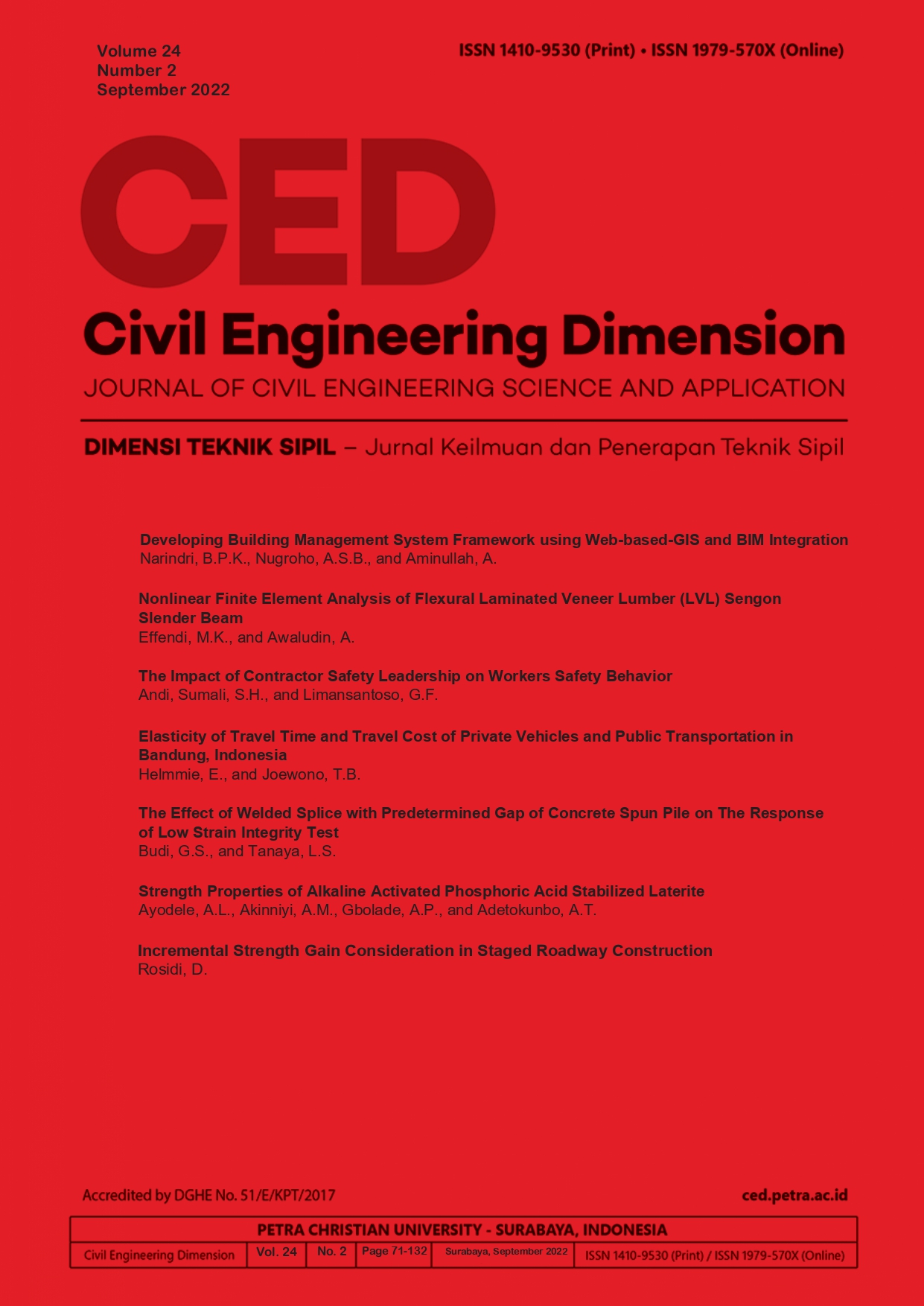

The Effect of Welded Splice with Predetermined Gap of Concrete Spun Pile on The Response of Low Strain Integrity Test

DOI:

https://doi.org/10.9744/ced.24.2.109-114Keywords:

Low strain, dynamic test, pile integrity test, sonic pulse echo, precast concrete pile, spliceAbstract

This paper presents the velocity wave of concrete spun piles with welded splice. The stress wave velocity was recorded using Pile Integrity Test. Two specimens were prepared in the experiment. The first sample was prepared visually no gap between the two end-plates of connected piles, while the second specimen was prepared by inserting 5mm thick steel plate into the splice to create a gap in its connection. The results show that a spike of reflecting stress wave still develops at the splice with and without gap, regardless the splice was welded in full circle. The relatively high spikes of reflecting waves at pile toe are noticed for both specimens with and without gaps. It shows that the full welded splice able to transfer stress wave velocity. A good quality of welded splice can be indicated by the reflecting wave at the pile toe, regardless the reflecting wave development at the splice.

References

ASTM D6760-16 (2016), Standar Test Method for Integrity Testing of Deep Foundations by Ultrasonic Crosshole Testing, ASTM International, West Conshohocken, PA. www.astm.org

ASTM D7949-14 (2014), Standar Test Method for Thermal Integrity Profiler of Concrete Deep Foundations by Ultrasonic Crosshole Testing, ASTM International, West Conshohocken, PA. www.astm.org

ASTM D 5882-16 (2016), Standar Test Method for Low Strain Impact Integrity Testing of Deep Foundations, ASTM International, West Conshohocken, PA. www.astm.org.

Rausche, F., Likins, G., and Hussein, M., (1988) Pile Integrity by Low and High Strain Impacts, Application of Stress-Wave Theory to Piles, ed Bengt H. Fellenices, BiTech Publisher, Vancouver, pp. 44-45.

Morgano, C. M. (1989) Capabilities of Pile Integrity Testing, PDA Users Day, Cleveland – Ohio.

Rausche, F., Likins, G. E., & Shen, R.K. (1992). Pile Integrity Testing and Analysis, Proceedings, 4th International Conference on the Application of Stress-Wave Theory to Piles, Netherland

Pile Dynamic Inc. (2008). PIT-W Professional Software for In-Depth Analysis of Data Collected with the Pile Integrity Tester Quality Assurance for Deep Foundations. www.pile.com

Standard Test Method for Low Strain Impact Integrity Testing of Deep Foundations 1. (n.d.). www.astm.org,

Luo, W., Chen, F., & Hu, J. (2010). Improvement of Low Strain Pile Integrity Test. (researchgate.net)

Promputthangkoon, P., Swasdi, S., & Kuasakul, T. (2018). Interpretation of pile integrity test results obtained from model concrete piles having two defect locations. International Journal of GEOMATE, 15(47), 132–138. https://doi.org/10.21660/2018.47.GTE23

Webster, K., Rausche, F., & Webster, S. (2011). Pile and shaft integrity test results, classification, acceptance and/or rejection. TRB 90th Annual Meeting, Washington, D.C.

Liang, L., & Rausche, F. (2011). Quality Assessment Procedure and Classifications of Cast-in-Place Shaft Using Low Strain Dynamic Test.

Santosa, N. and Leonardo, A. (2022) Hubungan Respons Pile Integrity Test dengan Besarnya Retak Fondasi Tiang, Skripsi, Petra Christian University

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Dr. Gogot Setyo Budi, Levin Tanaya

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:- Authors retain the copyright and publishing right, and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) followingthe publication of the article, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).